Project Overview

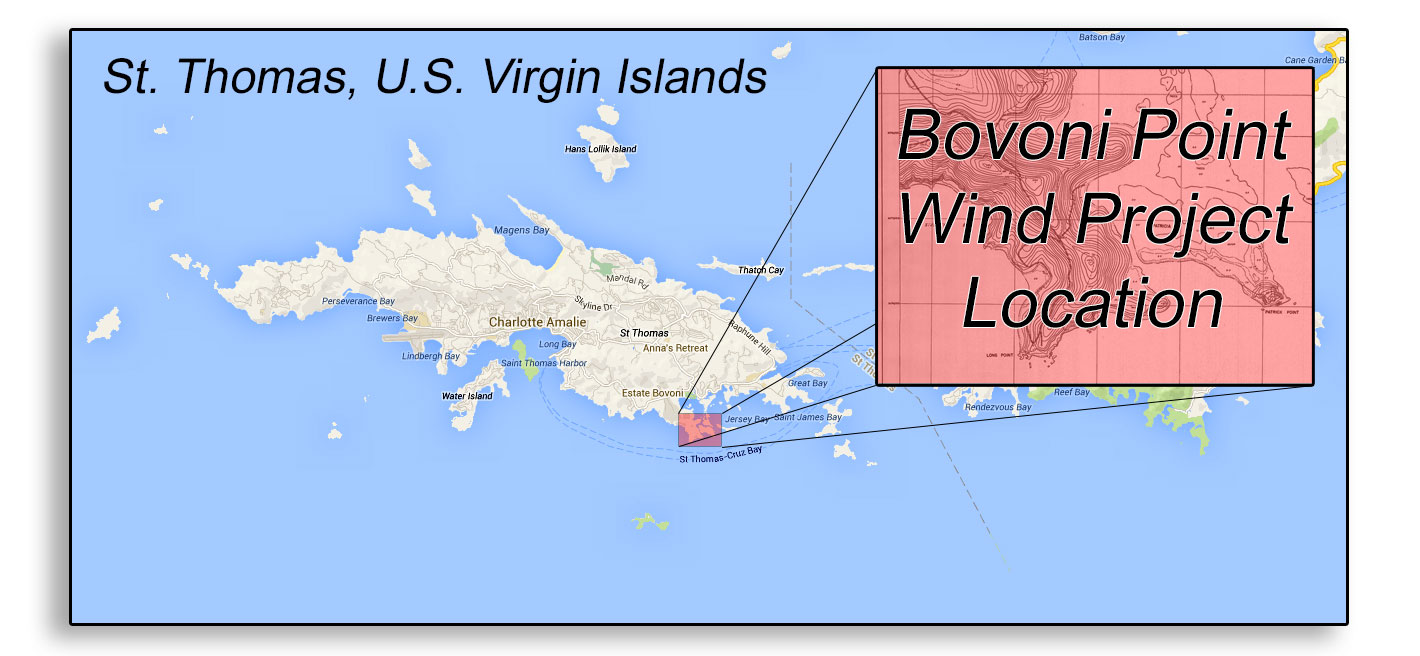

In May of 2017 Advance Power, LLC responded to a "Request for Proposals for the Supply of 10 MW of Electric Power Generation from Wind Energy Resources by means of a Power Purchase Agreement From Qualified Facilities" issued by the US Virgin Islands Water and Power Authority (WAPA). Subsequently, in the fall of 2017 Advance Power was selected to build a turnkey installation wind power generation plant for WAPA at Bovoni Point.

It has been determined that commercially viable wind is available at Bovoni Point, which is located on the southeastern portion of St. Thomas. The Bovoni Point location provides for an unobstructed view facing the prevailing east-southeastern trade winds. Additionally, because of the industrial nature of the Bovoni Point land area in general, which contains the island’s landfill and the Virgin Island’s Waste Management Authority’s methane power generation facility this site is well suited for commercial wind development.

viable wind is available at Bovoni Point, which is located on the southeastern portion of St. Thomas. The Bovoni Point location provides for an unobstructed view facing the prevailing east-southeastern trade winds. Additionally, because of the industrial nature of the Bovoni Point land area in general, which contains the island’s landfill and the Virgin Island’s Waste Management Authority’s methane power generation facility this site is well suited for commercial wind development.

As a renewable power system, onshore wind power generation is one of the most cost effective methods of renewable power systems available today, with literally thousands of megawatts having been installed worldwide over the past several years. The proposed land based wind turbine facility proposed for Bovoni Point uses proven and time tested commercial wind turbine technology, engineering, construction practices, implementation methods and more.

Advance Power Video Rendering of Bovoni Peninsula Wind Project - Song "Digital Dialogue" by Jordan Sovis

The Bovoni Point wind turbine facility will ultimately provide reliable competitively priced power for many years to the US Virgin Islands community in a proven, durable and reliable fashion. The wind power system is timely and exactly the renewable energy component missing in the overall power mix needed for the island.

Since the proposed wind turbine installation is a completely renewable power generation facility, and does not consume any petroleum based power generation fuels, eliminating the logistical need for resupplying the facility with LNG, diesel or other heavy fuels for combustion purposes. In practical terms this means there is no increased traffic or wear and tear on existing island infrastructure specifically ports and roads to continuously transport fuel to the wind power plant for the life of the facility.

Wind Turbine Technology

Selection Criteria

In developing the Bovoni wind project and after considering the long-term operational requirements of the peninsula, its surroundings, available wind resources, logistics, economics, technologies and many other factors. Advance Power carefully analyzed and evaluated many different wind turbines (geared vs. DirectDrive, etc.) and related performance characteristics. Advance Power ultimately selected the LEITWIND LTW80 1.65 MW IECIIIA as the best technically designed and commercially viable wind turbine for this very challenging site.

The LTW 80 1.65 MW wind turbine is manufactured by LEITWIND, a subsidiary of the HTI (High Technology Industries) Group. The HTI Group consists of seven high-tech companies doing business around the world with roots going back to 1888. The HTI Group has a long history working with DirectDrive technology across several industries. Backed by the HTI Group’s synergies, LEITWIND produces gearless wind turbines from sizes of 0.25MW up to 3.0MW.

LEITWIND LTW80 1.65 MW DirectDrive Wind Turbines

Specifically for the Bovoni wind project, Advance will build a wind turbine array on Bovoni Point consisting of six (6) for a total nameplate capacity of 9.0MW (the equivalent of 10MW using geared turbines). These turbines will be sited and distributed at key locations on the lower portion of the peninsula to take full advantage of the unobstructed eastern trade winds. The LTW80's efficient design and rugged construction has as outstanding and proven safety record and reliability, even in the most demanding conditions.

Video Courtesy of LEITWIND

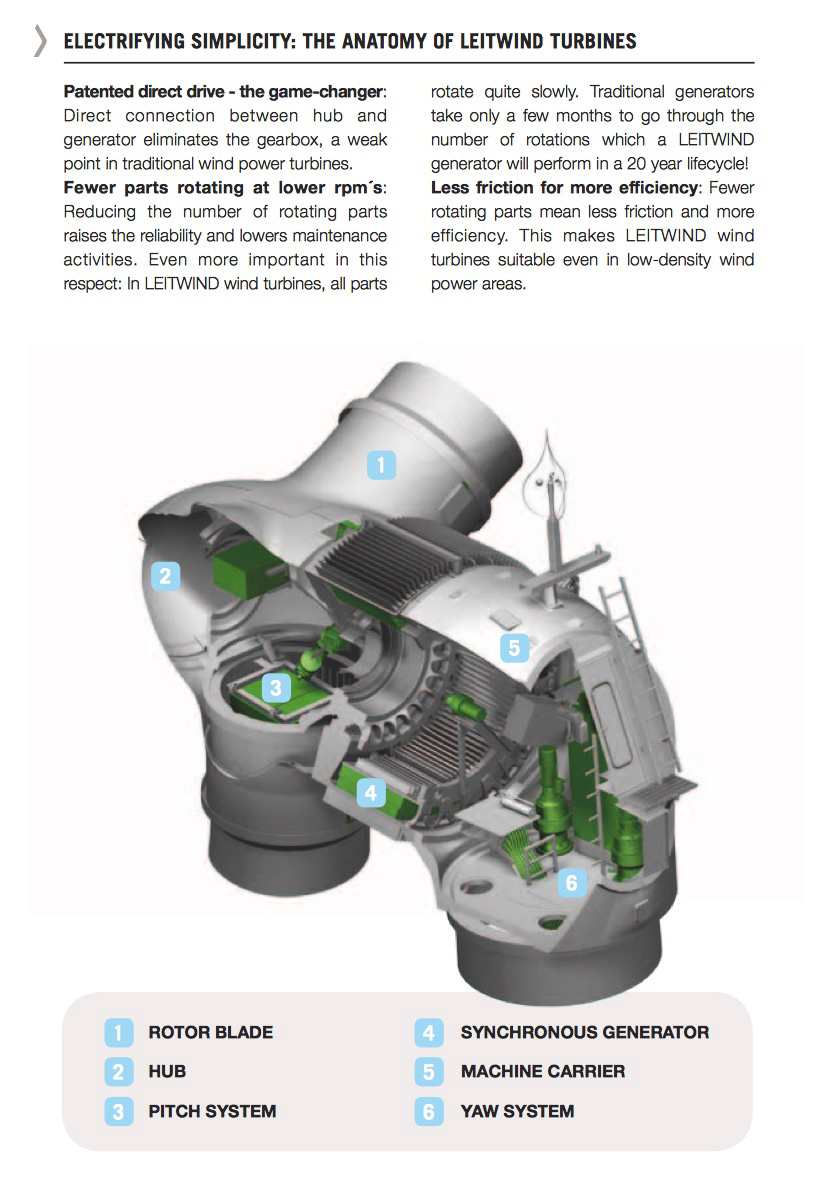

The LEITWIND LTW80 wind turbines employ a horizontally mounted upwind DirectDrive system, and the nacelle has three main components consisting of: (1) Hub assembly; (2) Electrical generator, and; (3) Machine carrier. The LTW80 utilizes a synchronous generator with a permanent magnet DirectDrive synchronous system.

The generator system is directly coupled to the rotor ensuring high performance, eliminating the need for a gearbox, while at the same reducing the number of moving parts and thus maintenance. The generator forms an integral part of the structure and is directly mounted to the main frame, which is in turn mounted on a low profile sixty-five (65) meter tower.

The rotor (blade) is designed with exchangeable modular permanent magnets with flux concentration. Also, the stator winding consists of exchangeable modular coils with tooth concentrated windings. The turbine's modular design incorporates a dual circuit system to provide operational redundancy. Having fewer components than geared turbines, the DirectDrive generator ensures increased efficiency and easier transport and assembly.

"Cut Away View of Hub Assembly, Generator & Machine Carrier - Graphics Courtesy of LEITWIND"

The LTW80 consists of three blades per turbine which have variable speed and automatic pitch and yaw regulation. Each individual blade has a total length of thirty-nine (39) meters, for a total rotor diameter of 80.3 meters, and a total blade sweep area of 5,064m2. At the top of the blades’ rotation, the height is 105 meters (344.5 feet AGL). The rotor has an active pitch control system and variable rotational speed of approximately 17.8 rpm.

The design of the LEITWIND DirectDrive wind turbines vastly simplifies assembly, and also produces superior maintenance and operational reliability. These LEITWIND turbines are extremely reliable, robust (and are being specially engineered to be hurricane resistant for the Bovoni site), safe, and been successfully deployed around the world (additional details described below).

Delivery of the energy generated by the Bovoni wind project will be through an underground electrical collection system designed to a point of interconnection (POI) which will include the necessary electrical equipment to connect to WAPA electrical distribution system, the POI will be built near the northwest area of the peninsula close to Bovoni Road.

Key LTW80 Performance Features

The power curve or expected/measured power output at a given wind speed is predicated on the efficiency of an individual wind turbine. Numerous factors such as blade design and other turbine features, including whether gearboxes are utilized (instead of DirectDrive technology), impact turbine efficiency. Gearless/DirectDrive wind turbine power curve outputs are generally 3% to 4% more efficient when compared to geared wind turbines. This is because gearboxes cause loss of power from the low-speed input shaft to the high-speed output shaft, which drives the generator.

This critical component is specifically designed and engineered for the particular operating environment located at Bovoni Point. Generally wind turbine blades are built to harvest the maximum amount of energy from the available wind. Many factors determine the aerodynamic efficiency and performance characteristics of a wind turbine generator (WTG) blade, including the design, shape, pitch, and length.

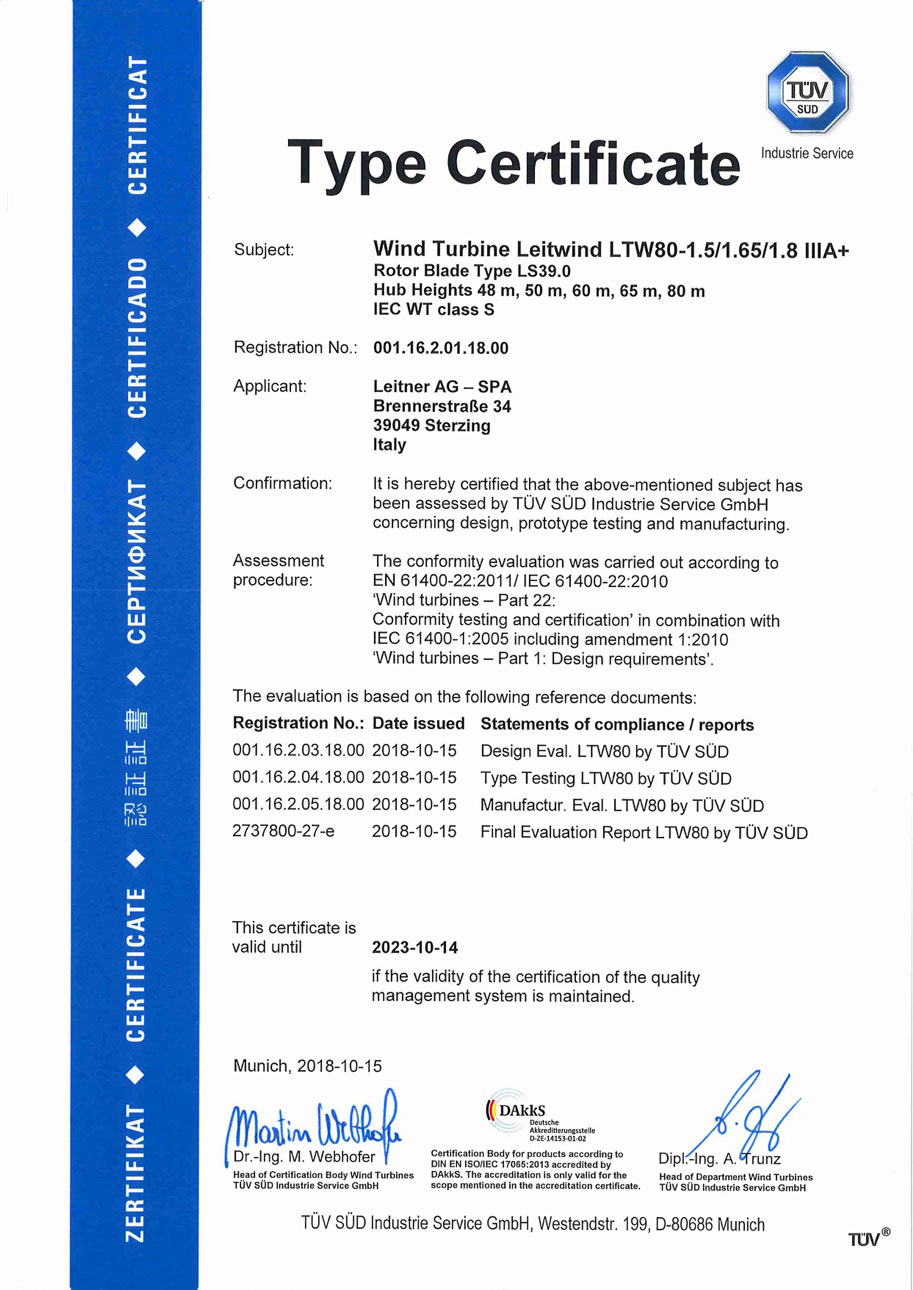

Another critical factor for the wind turbine blades to be used at Bovoni Point is their strength: They are designed to survive a high wind event for short duration periods. The LTW80 1.65 MW turbine has a rotor diameter of 80.3 meters, with each individual blade being 39 meters long. The LTW80's 39-meter long rotor blades are so strong and robust that they are type certified by TUV SUD Industrie Service for WT-class IIIA in accordance with GL guidelines.

"Wind Turbine Rotors Being Attached To Hub Assembly - Image Courtesy of LEITWIND"

In addition to the class IA blade certification, LEITWIND will further increase the strength of the rotor blades to be used at the Bovoni site by using a higher strength class of fiber, exceeding the Hurricane Class 1A certification requirement under the DNV-GL technical guidelines.

The blades on the LEITWIND LTW80 1.65 MW turbines are very strong and robust, particularly for the type of wind resource found at Bovoni Point. By contrast, larger size wind turbines must use larger and longer blades to be properly matched to the larger size turbine's capacity. To reduce weight, those longer blades are weaker, and far more susceptible to damage or failure in high wind events or hurricanes. So, put plainly, Advance Power will use blades that are shorter, stronger, and far better suited to the conditions at Bovoni Point.

The LTW80’s DirectDrive technology does away with the WTG’s gearbox, eliminating the most complicated component. By eliminating the gearbox, the LTW80’s DirectDrive solution has fewer and slower rotating parts, less wear, and therefore improved long-term reliability and reduced maintenance. The LEITWIND DirectDrive system uses permanent magnets, has a robust cooling system, and places all the electrical equipment on the inside. The machine carrier provides overall good accessibility to the system from inside the nacelle.

Another advantage of LEITWIND LTW80 turbine is its dual circuit design. If one of the two primary electric circuits has a problem, this modular dual circuit design allows for the easy removal of a single component, or a series of components, by skilled technicians in a matter of hours. For the past several years, the average technical availability of all LEITWIND wind turbines was 97.6% and 98.8% for the most recent reporting year.

DirectDrive technology does away with the need for the primary gearbox, so large cranes are never required to remove a failed gearbox. And because the reduced size of the modular components can quickly be raised and/or lowered using the LTW80’s internal service winch installed in each nacelle, the LTW80’s turnaround time to service or to replace a failed component is much shorter, allowing a much quicker return to 100% output capacity. Any internal circuit repairs can be made without the need for an external crane (which may not even be available on St. Thomas at the time service might be needed).

Another very important feature of the dual circuit design of the LEITWIND LTW80 is its power restoration ability -- if one of the turbine’s primary circuits should require removal or service, once those components are removed, the wind turbine can then immediately be brought back to an operational status at a reduced output of 50% capacity running on the remaining circuit until the necessary repairs are completed. Geared wind turbines can’t do that because in geared turbines, if the primary gearbox fails it generally has to be removed using a crane (which may not be available on St. Thomas), and the entire turbine is completely out of service until the gearbox is repaired or replaced.

Advance has executed a twenty (20) year O & M Agreement with LEITWIND, which provides for a parts inventory to be maintained on St. Thomas. In addition, if parts are needed that are not already on St. Thomas, because of their smaller and modular design, any such replacement parts can generally be flown to the island in a matter of days for timely delivery and installation.

Advance’s proposal to install six (6) LTW80 1.65 MW WTGs builds in systems redundancy by utilizing a greater number of wind turbines. Advance considered fewer and larger nameplate capacity wind turbines, specifically three (3) 3.0 MW wind turbines, for Bovoni Point. After considering all aspects of that option, Advance eliminated those larger turbines from consideration because larger wind turbines are not designed for this site when factors like logistics, redundancy, reliability, hurricane risk, and blades are considered.

Regarding redundancy, if three (3) 3.0 MW turbines were employed at Bovoni, and one of those three (3) turbines failed, that translates to an outage of one-third (33.3%) of the entire capacity of the wind installation. By contrast, if one of the six (6) LTW80 1.65 MW turbines failed, that would mean a capacity reduction of one-sixth (16.6%). [Note: And that is only if both of the LTW80 1.65 MW turbine dual circuits failed at the same time, because if only a single circuit failed, overall capacity reduction would only be 8.3%.]

Cutaway Graphics Courtesy of LEITWIND

Using six (6) LEITWIND LTW80 1.65 MW turbines allows Advance Power to optimize the WTG's configuration on Bovoni Point. Proper siting and separation of the wind turbines is critical, and using multiple smaller turbines allows Advance Power to better use the available area, minimize wake losses and shadowing, and maximize power output.

Given the roughness and the complexity of the topography at the Bovoni site, and the available wind resource, the selection of six (6) LEITWIND LTW80 1.65 MW turbines allows placements, which better utilize the higher and lower elevations of the site with the best exposure to the east-north easterly trade winds.

The smaller size and significant technical advantages of the LEITWIND LTW80 1.65 MW wind turbines allows for installations in difficult and remote locations like Bovoni Point. A specific logistic study and plan has been developed and tailored for the Bovoni Point site’s specific characteristics and grid requirements, and the LTW80s have great logistics and transportation advantages for the Bovoni site.

The nacelle of the LTW80 has three distinct segments: hub assembly, generator, and machine carrier. Because the nacelle module is segmented into individual pieces, each piece weighs less and is simpler to handle and transport. On site, they are individually lifted and assembled, one at time, on the towers. These smaller and lighter segments require smaller cranes.

All sections of the nacelle are movable through the existing port facilities on St. Thomas, and will be transported at night over existing roads to minimize disruption to the public. A comprehensive logistics and transport plan for the Bovoni wind project completely removes any need to disturb any sensitive coastal area regarding moving wind turbine components eliminating all potential risk to the Bovoni Point shoreline area.

Energy Production

In the simplest terms the wind turbines produce electricity when the wind blows flows over the wind turbines, the wind’s kinetic energy is causes the wind turbines blades (rotors) to rotate. Generators inside the wind turbines transform this kinetic energy into electricity. The electricity generated by the Bovoni wind project will be transformed and converted it to the right voltage to be delivered to WAPA's power grid through an underground "collection system" to a point of interconnection.

The physical phenomenon on which generators rely is magnetic induction. Induction in the form of voltage occurs when either a conducting coil is placed in a changing magnetic field or when the coil moves around in a magnetic field. The mechanical force of the blades drives the rotor of the generator. This creates a rotating magnetic flux inside the stator of armature coils. There are different types of generators, the wind turbines to be used at Bovoni Point use synchronous generators.

The wind turbines at Bovoni Point will be mounted at a height of 65 meters (213 feet), on re-enforced tubular steel towers which will support the “nacelle,” which is comprised of the hub assembly with the three attached rotors, machine carrier, generator, and control systems.

Real time wind measurements are continuously taken providing these input to the turbine control systems, which direct the turbine to rotate and face the strongest wind and optimizing the angle or "pitch" of its rotors to capture the maximum amount of energy.

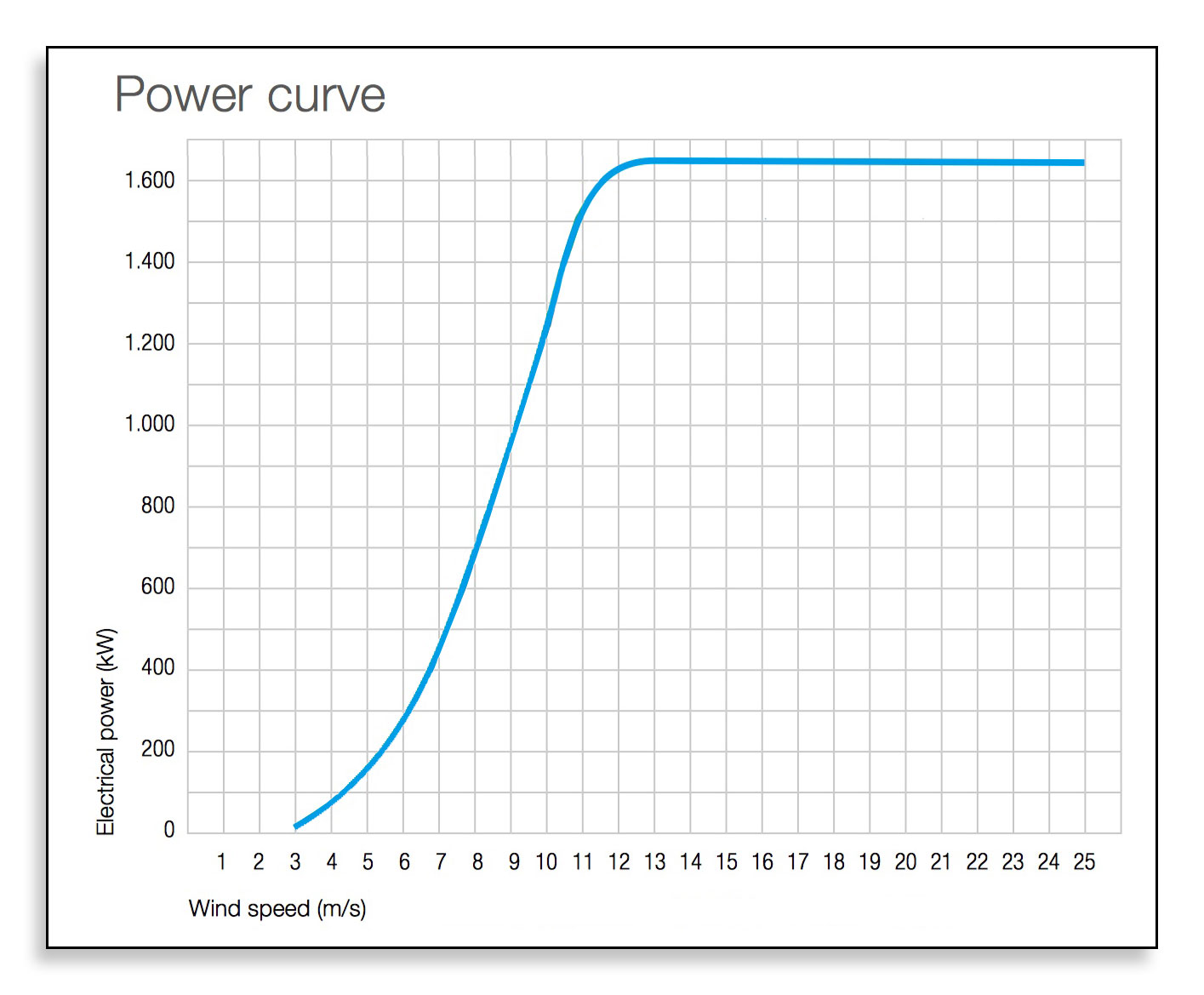

The wind turbines at the Bovoni wind project will start to generate electricity when wind speeds reach 3.5 meters per second (7.8 mph), known as the cut-in speed. The turbines will shut down if the wind is blowing too hard (roughly 16.7 meters per second or 55 miles an hour) to prevent damage to the wind turbines.

On an annual basis, the Bovoni wind turbines are expected to generate usable amounts of electricity the majority of the time, generally in the range of 70% to 90%. If for example the wind at a turbine reaches the cut-in speed of 3.5 m/s, the turbine will start generating electricity.

The higher the wind speeds the more electrical power output increases until the wind turbine reaches its maximum operating capacity. The amount of electricity that a wind turbine can produce at different wind speeds is a function of the wind turbine's operational efficiency which is driven by the wind turbine's engineering design. The electrical output at various wind speeds is measured in terms of a measured "Power Curve", as shown below;

Image Courtesy of LEITWIND

On an annual basis wind energy production is also commonly measured in terms of a production "Capacity Factor". A wind turbine's capacity factor is the measured amount of electricity a wind turbine produces in a given year (8,760 hours) relative to its maximum output potential in that year. Due to the constantly changing wind speeds (called indeterminacy) the capacity factor is a more standardized way to understand the wind turbine's total potential energy production on an annual basis.

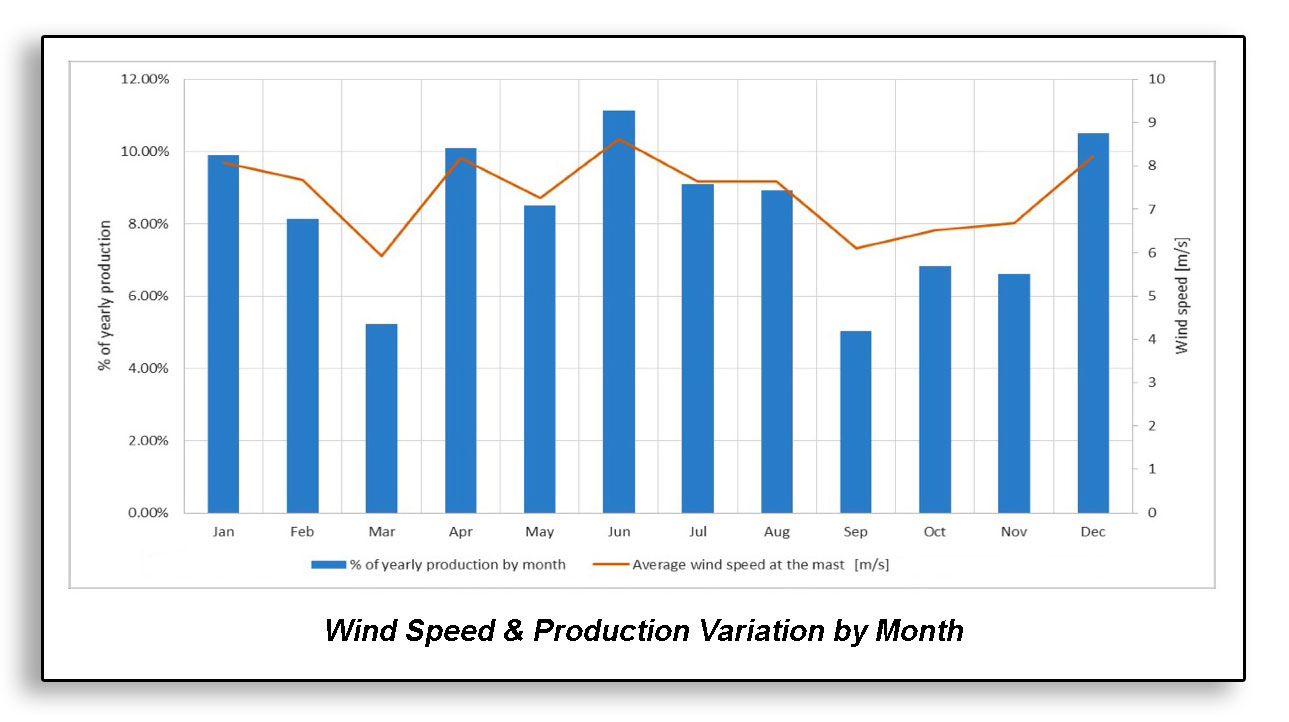

After the site assessment of Bovoni Point was completed and the collected wind data was analyzed, it was then applied to the performance characteristics of the LEITWIND LTW80 1.65 MW DirectDrive wind turbines. With this valuable information our engineers were then able to forecast the energy to be produced by the Bovoni wind project on a seasonal and monthly basis as represented by the histogram below;

Image Courtesy of LEITWIND

In evaluating the suitability of the wind and the Bovoni wind site conditions for the LEITWIND LTW80 1.65 MW wind turbine generators (WTG) the IEC 61400-1 standard was used. The IEC 61400 standards specify the additional design requirements made to ensure that wind turbines are appropriately engineered against damage from hazards within the planned lifetime. The standard concerns most aspects of the turbine life from site conditions before construction, to turbine components being tested, assembled and operated.

Among the different parameters listed in the IEC Standard "Design Requirements", the following design parameters have been analyzed for the proposed Bovoni turbine locations at hub height: turbulence intensity, wind speeds, inflow angle, wind shear among others.

Operations & Maintenance

Advance Power will not only build the Bovoni wind project, but its team will also operate the facility. From a project development and operational standpoint, Advance Power has a very close working relationship with LEITWIND and is proud to be working with LEITWIND on developing the Bovoni wind project and its subsequent operation.

LEITWIND's extensive experience and expertise around the world is exceptionally well suited for the Bovoni project. LEITWIND's long-term commitment and participation in working with Advance Power to develop the Bovoni wind project has been nothing less than extraordinary.

While LEITWIND is supplying the wind turbine generators (WTG) from the Bovoni wind project, LEITWIND's commitment far exceeds the role of the any other traditional wind turbine manufacturer. Unlike many of the larger wind turbine manufacturers whose primary role is only manufacturing turbines, LEITWIND does not’t just manufacture the turbines.

Specifically for the Bovoni wind project LEITWIND's role is expanded to coordinate and incorporate several project development aspects including the delivery and associated logistics of the all wind turbine components to St. Thomas, overland transportation from the port to the Bovoni Point peninsula, supplying & delivering cranes to site, wind turbine component & tower assembly & erection, turbine wiring, and comprehensive wind turbine commissioning to full scale commercial production.

And most remarkably, for the first time in LEITWIND's history, for the Bovoni wind project, LEITWIND has agreed to a long-term twenty (20) year operations and maintenance (O&M) agreement for the project. This is an exceptional commitment by LEITWIND as the turbine manufacturer to long-term success of the project. See the quote from LEITWIND in the "WindChannel" publication about this exceptional agreement, below;

"LEITWIND has committed to deliver the wind turbines in a standard Engineering, Procurement and Construction (EPC) contact. In addition to the supply contract, a "full-service" maintenance contract for the wind farm over a fixed period of 20 years has been signed. This is the first time that LEITWIND has offered a comprehensive and long-term maintenance contract of this kind. It shows the confidence both LEITWIND and the customer put in the reliability of the technology and the product." ------ WindChannel - News From LEITWIND World NR 4 | 2018

As part of this special arrangement, LEITWIND will also provide continuous remote wind turbine mounting twenty-four hours a day, seven days a weeks, three hundred and sixty five days a year (24/7/365), with extended remote operational control & other real-time turbine functionality.

Hurricane Resiliency

Hurricane survivability as it relates to the wind turbines is a common question Advance Power's team is frequently asked. The short answer is fairly straight forward in that basically there is no man made structures, including the wind turbines that Advance Power can build that mother nature cannot destroy. Consequentially, our team would never represent that the wind turbines at Bovoni Point are "hurricane proof".

However, there are strategies and configurations that can be implemented to increase the chances of the wind turbines surviving high wind events and/or indirect or glancing encounters by taking steps to make the wind turbines "hurricane resistant". See what the turbine manufacturer LEITWIND says in the "WindChannel" publication regarding "Hurricane Resiliency", below;

"Leading edge technology, customer orientation and flexibility were most certainly key factors in contracting LEITWIND for this project. LEITWIND was able to prove its competence with regard to technical challenges of such a complex project. A convincing factor was particularly the special configuration of the systems designed to withstand hurricanes and typhoons of GL Tropical cyclone class 1." ------ WindChannel - News From LEITWIND World NR 4 | 2018

For starters the wind turbine foundations will be specially designed and re-enforced to withstand higher than normal wind loads. The wind turbine towers themselves will be custom designed with thicker steel walls and will be built in a low profile configuration that will further reduce the potential high wind event exposure.

The primary exposure or risk component for the wind turbine is the blades, and the item that would typically be the first major component to fail structurally in the event of a direct hit from a hurricane. In fact this is one of the main benefits of the LTW80 wind turbine, its blades are extremely strong and robust.

Speaking in strictly historical terms while several hurricanes have impacted the Virgin Islands over the years, from the available records at the National Oceanic and Atmospheric Administration (NOAA) their tracking maps do not indicate any "direct" hurricane hits specifically on the Bovoni Point peninsula itself. But of course the term "direct hit" is relative in terms of identifying the path of a hurricane in narrow terms, simply due the sheer size of the event.

Even with a proven history of survival the LTW80 blades and or any other wind turbine blade for that matter would not be likely to survive a direct hit from a high category hurricane, it is simply an operational risk associated with wind turbines placed in hurricane prone areas. The wind turbine towers and foundations would have a much higher chance of survival.

Also for reference the electrical collection system for the Bovoni wind project will be completely underground and have no exposure to the any sustained high wind event. Additionally, the wind turbine array itself will have its own backup electrical power system in the event and likelihood of power failure from the grid during a storm in order to continue operating the turbines' sub-systems, including the yaw drives, rotor pitch adjustment drives, etc.

Type Certificate Image Courtesy of LEITWIND

The LEITWIND LTW80 turbine design has passed rigorous testing and certification by the GL Renewable Certification group to withstand hurricanes and typhoons of GL Tropical Cyclone Class 1. The GL Renewable Certification group works with the Wind and Marine Energy Committee and which consists of representatives from public authorities, wind turbine and component manufacturers, engineering consultants, institutes, universities, technical associations and insurance companies.

Project Performance Risk

As the Bovoni wind project is structured under a "power purchase agreement" (PPA) model, the majority of the project's financial performance and operational risk is borne by Advance Power. Under the PPA model the US Virgin Islands Water and Power Authority (WAPA) as the buyer, will purchase power generated by the Bovoni wind project from Advance Power, as the seller.

There are several advantages to this "Public-Private Collaboration" for WAPA under this model, first and foremost is primarily the financial risk avoidance aspect.

The first major advantage to WAPA is that the Bovoni wind project is "budget neutral" to WAPA (and by extension the Virgin Islands rate payers), meaning no financial impact to WAPA's budget or up front capital is required from WAPA to build the Bovoni wind facility. Essentially under the PPA model structure approach the initial capital financial risk is shifted to Advance Power.

The capital cost to build the entire wind facility at Bovoni Point is provided by Advance power and/or through the commercial capital markets. No US Virgin Islands tax payer money or governmental funding will be used to build the facility.

Under the PPA approach Advance Power will fund and build the wind installation for WAPA and enter into a long-term power purchase agreement with WAPA, who will purchase power from the wind facility.

The means the real value of the Bovoni wind project is that it delivers a long-term power hedge under the PPA, that results from the contracted rate structure under the agreement which in turn reduces the pricing uncertainly associated with generating power from fossil fuel based power generation.

Secondly, WAPA will not bear the operational risks associated with running and maintaining the Bovoni wind project, the operation performance risk is the responsibility of Advance Power. Advance Power is only paid for power it produces from the Bovoni wind facility, while WAPA's obligation is to purchase the electrical power that is produced and delivered to its grid.

In the simplest of terms the PPA creates a basic "Value" proposition, WAPA only has to pay for the "value" of electricity received by it while Advance Power only gets paid for the "value" of electricity it delivers.